ASTM A1096/A1096M-15

This test method describes procedures for evaluating bond of individual steel wire, indented or plain, for concrete reinforcement. The bond determined by this test method is stated as the tensile force needed to pull the wire through the cured mortar in a cylindrical steel casing.

RJ Peterman & Associates conducted the initial testing that directly led to the development of this test standard

In 2008, Dr. Peterman began working as a technical consultant on a project involving premature failures of pretensioned concrete railroad ties. Because of the specific failure mechanism, it was suspected that the bond between the prestressing wire and surrounding concrete might be a possible contributor.

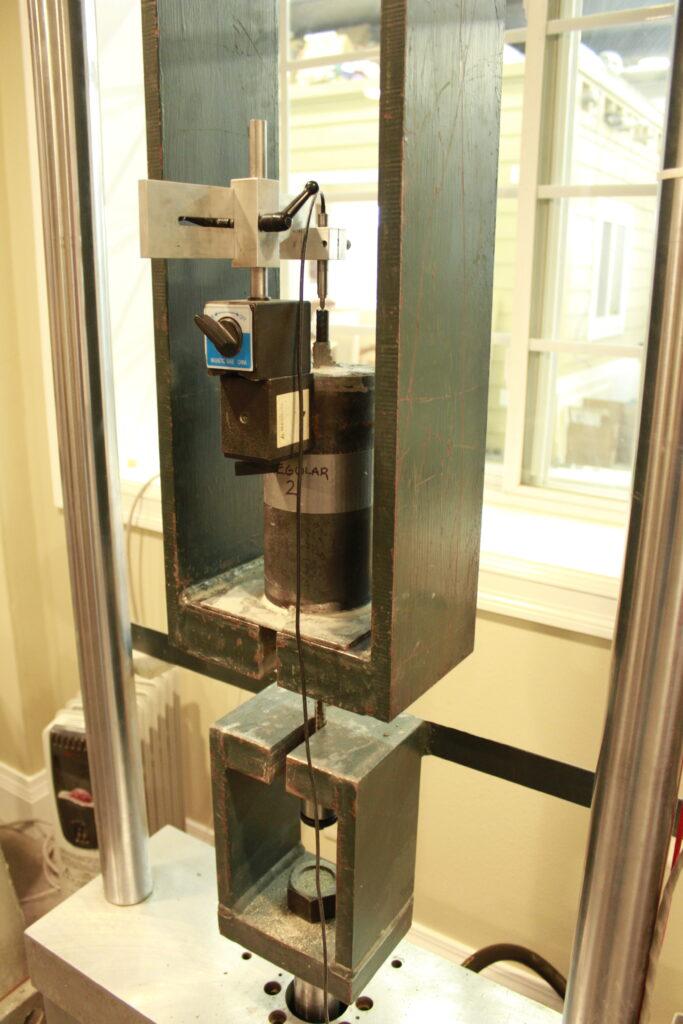

In order to quantify the difference in the inherent bonding capability of various indented prestressing wires, RJ Peterman & Associates, Inc. conducted pullout tests on specimens with varying embedment lengths.

Then. from 2011-2014, Dr. Peterman was the Lead-PI on a $2.1 million interdisciplinary research project at Kansas State University titled "Quantifying the Effect of Prestressing Steel and Concrete Variables on the Transfer Length in Pretensioned Concrete Crossties".

As part of this work, the pullout test methodology was refined by Dr. Peterman and one of his graduate students, Matthew Arnold, to include a standard sand (Ottawa Sand) and standard batch proportions. Using this refined method, the pullout test results had excellent correlation with resulting transfer lengths of test specimens utilizing the same wires. As a result, the refined pullout test procedure was officially adopted as ASTM A1096 in 2015.