Evaluation of Prestressing Wire and Cylinder Plate from PCCP Segments

Prestressed Concrete Cylinder Pipe (PCCP) relies on the confining pressure of helically-wrapped prestressing wires to resist the internal fluid pressure. However, prestressing wires that are exposed to excessive heat during the manufacturing process are subjected to dynamic strain aging (DSA) which, in turn, makes them extremely sensitive to hydrogen embrittlement.

RJ Peterman & Associates assists clients with the evaluation of existing PCCP segments by performing the following tests:

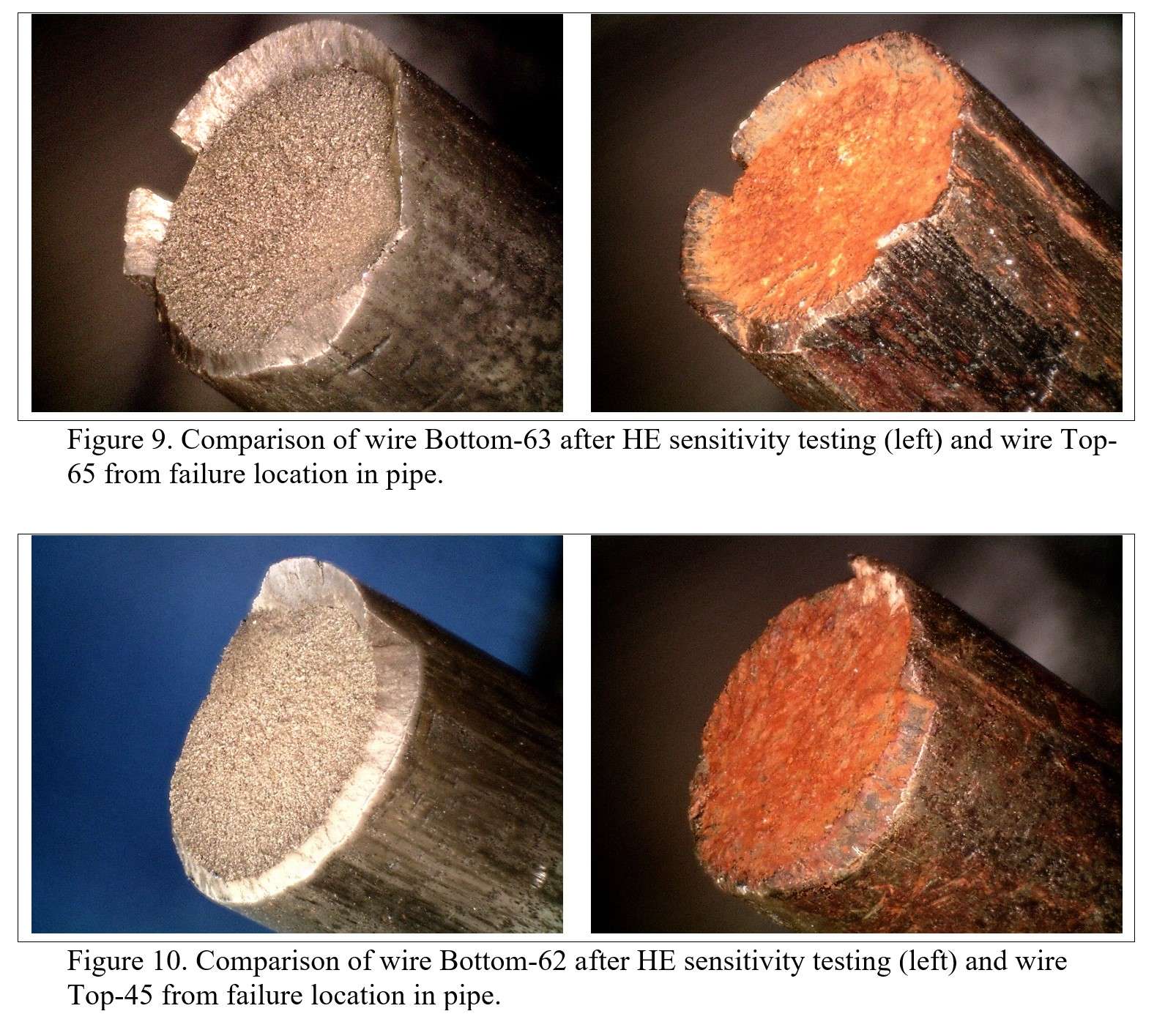

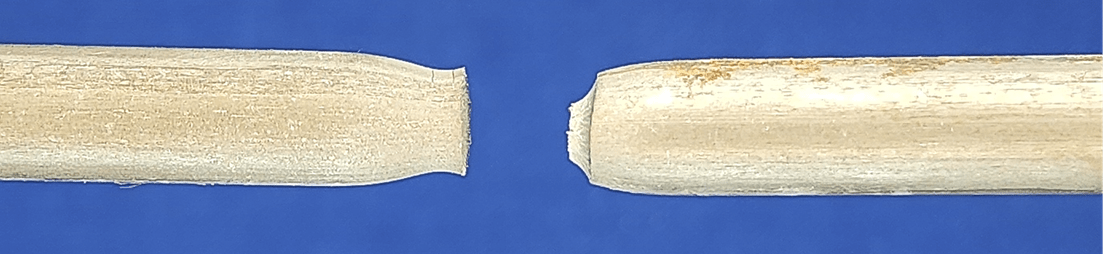

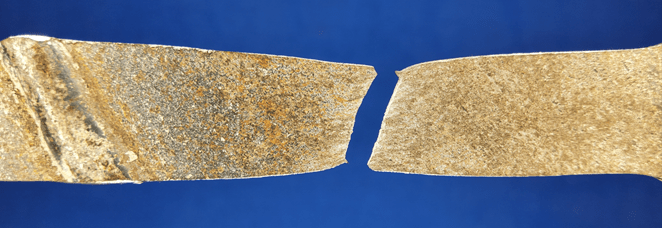

- Microscopic analysis of prestressing wires and failure surfaces

- Hydrogen embrittlement sensitivity tests, in accordance with ASTM A1032

- Wire torsion tests, in accordance with ASTM A938

- Wire tensile tests, in accordance ASTM A370

- Cylinder plate tensile tests, in accordance with ASTM A370 (typically we conduct tensile tests of both the base metal and the weld within the tested gage length)

After conducting the physical testing, a summary report is written which compares the material properties of the wire and cylinder plate with the standards that were in place at the time of fabrication, and also contemporary standards. This information is useful for evaluating the health of intact PCCP pipelines whenever maintenance is being performed. Additionally, when a PCCP segment fails, this information is vital towards understanding the failure mechanism and making decisions about repairing or replacing large portions of a PCCP pipeline adjacent to a failed segment.